A transfer switch wiring diagram is a visual guide for connecting power sources and loads, ensuring safe and efficient electrical transitions between primary and backup systems․

It provides detailed schematics for Automatic Transfer Switches (ATS) and manual configurations, helping installers understand parameter settings and interlocking mechanisms for reliable power supply management․

1․1․ Understanding the Purpose of Transfer Switches

Transfer switches are essential for ensuring uninterrupted power supply by automatically or manually switching between primary and backup power sources․

Their primary function is to detect power failures and seamlessly transition loads to a backup generator or alternate power source, minimizing downtime and protecting sensitive equipment․

These switches are critical in residential, commercial, and industrial settings, preventing electrical feedback and ensuring safe, reliable power transitions between utility and backup systems․

Both Automatic Transfer Switches (ATS) and Manual Transfer Switches (MTS) are designed to simplify power management, offering a secure connection process outlined in detailed wiring diagrams․

1․2․ Importance of Wiring Diagrams in Installation

Wiring diagrams are crucial for the correct installation of transfer switches, providing a clear visual representation of connections and components․

They ensure accuracy, preventing installation errors that could lead to electrical hazards or system malfunctions․

By following the diagram, installers can safely connect power sources, loads, and circuit protection devices, adhering to safety standards and manufacturer guidelines․

Wiring diagrams also simplify troubleshooting, allowing users to quickly identify and resolve issues during or after installation․

They are essential for both automatic and manual transfer switches, ensuring reliable power transitions and minimizing downtime․

Types of Transfer Switches

Transfer switches include Automatic Transfer Switches (ATS) for seamless power transitions and Manual Transfer Switches (MTS) requiring operator intervention, each suited for different applications and power systems․

2․1․ Automatic Transfer Switches (ATS)

An Automatic Transfer Switch (ATS) is a critical component in electrical systems, enabling seamless power transitions between primary and backup sources, such as generators, without manual intervention․

These switches are designed with advanced sensors and relays to detect power failures and automatically switch to the standby source, ensuring uninterrupted power supply․

ATS systems are widely used in commercial and industrial settings, where downtime must be minimized․

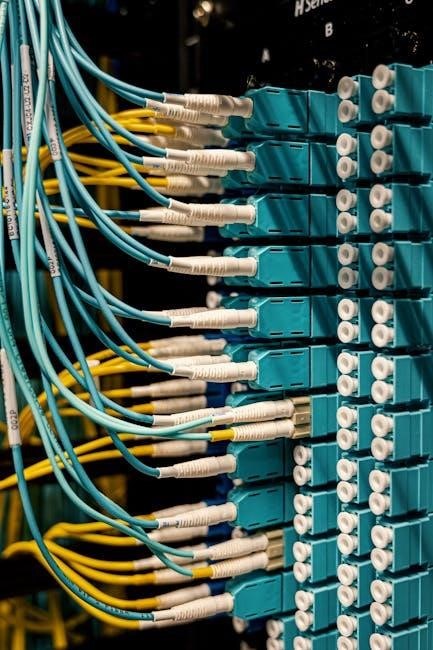

The wiring diagrams for ATS typically include detailed connections for sensors, relays, and interlocking mechanisms to prevent electrical feedback․

Models like the ATL500 controller offer both automatic and manual switching options, providing flexibility in operation․

Proper wiring ensures safe and efficient functionality, making ATS a reliable solution for critical power applications․

Earth leakage switches are often integrated to enhance safety standards․

Always refer to the manufacturer’s wiring diagram for specific parameter settings and connections․

2․2․ Manual Transfer Switches (MTS)

A Manual Transfer Switch (MTS) is a device that allows users to manually switch between two power sources, such as a primary utility line and a backup generator․

Unlike automatic switches, MTS requires physical intervention to transfer power, making it a cost-effective solution for smaller systems․

These switches are commonly used in residential and small commercial applications where continuous power is not critical․

The wiring diagram for an MTS typically includes connections for the main power source, backup generator, and load circuits․

Key components include the switch mechanism, wiring terminals, and sometimes indicators for the active power source․

MTS systems are simpler to install and maintain compared to ATS but require manual operation during power outages․

Always ensure proper grounding and circuit protection when wiring an MTS to prevent electrical hazards․

2․3․ Single-Phase vs․ Three-Phase Transfer Switches

A single-phase transfer switch is designed for systems with one live wire and one neutral wire, typically used in residential or small commercial setups․

It operates on a simpler circuit structure, making it cost-effective for lower power demands․

On the other hand, a three-phase transfer switch handles three live wires and one neutral wire, suitable for industrial or high-power applications․

Three-phase switches are more complex due to the need to synchronize multiple power lines․

Choosing the right type depends on the load requirements and the power supply system in place․

Always ensure the wiring diagram matches the phase configuration to avoid compatibility issues․

Proper installation is crucial for safe and efficient operation of the transfer switch․

Key Components of Transfer Switch Wiring Diagrams

Transfer switch wiring diagrams include power sources, load connections, relays, and interlocks to ensure safe and proper switching between primary and alternate power sources․ Circuit protection devices are also essential․

3․1․ Power Sources and Load Connections

In a transfer switch wiring diagram, power sources are clearly identified, such as the primary utility supply and the alternate source, typically a generator․ These sources are connected to the transfer switch to ensure seamless power transition․ The diagram also details how load connections are configured, showing which circuits or devices are powered by each source․ Proper labeling of wires and terminals is essential to avoid confusion during installation or troubleshooting․ The wiring diagram ensures that all loads are safely and efficiently transferred between power sources without risking overload or short circuits․

Understanding the connections between power sources and loads is critical for maintaining system reliability and safety․ The diagram provides a clear visual guide, making it easier to identify potential issues before they arise․ Always ensure that connections are secure and properly sized to handle the maximum expected load․ This prevents overheating or damage to the transfer switch and connected equipment․ By following the wiring diagram, installers can ensure that power sources and loads are correctly interfaced, providing a dependable power supply system․ Proper installation minimizes risks and ensures smooth operation during power transfers․

3․2․ Relay and Interlocking Mechanisms

Relay mechanisms in transfer switches are critical for automating the power switching process․ These mechanisms use electromagnetic relays or solid-state components to detect power loss and initiate a transfer․ The wiring diagram illustrates how relays are connected to sense the primary power source and trigger switching to the alternate source․ Interlocking mechanisms, either mechanical or electrical, prevent simultaneous connection of two power sources, ensuring safe operation․ In manual transfer switches, interlocks are often mechanical, while automatic switches rely on electrical or microprocessor-controlled systems․ Proper wiring of these mechanisms ensures smooth transitions and prevents electrical hazards․ Always follow the diagram to connect relays and interlocks correctly for reliable performance and safety․ This ensures the system operates as intended, avoiding potential damage or risks․ Proper configuration is essential for seamless power transitions and system protection․

3․3․ Circuit Protection Devices

Circuit protection devices are essential in transfer switch wiring diagrams to safeguard the system from overcurrent conditions․ Commonly used devices include circuit breakers and fuses, which interrupt the circuit when excessive current flows, preventing damage from short circuits or overloads․ Circuit breakers offer resettable protection, while fuses provide one-time use, melting to break the circuit․ Proper installation, as per the diagram, ensures protection for both the transfer switch and connected loads․ Correct ratings are vital: underrated devices may trip frequently, while overrated ones may fail to protect adequately․ Coordination between these devices ensures that the correct one trips first, maintaining safety and functionality․ Proper installation and maintenance are crucial for upholding safety standards and protecting both equipment and personnel․ These devices are fundamental to ensuring reliable and safe electrical system operation․

Safety Precautions for Wiring Transfer Switches

Always de-energize circuits before starting work․ Wear PPE, including gloves and safety glasses․ Follow lockout/tagout procedures to ensure equipment is safely disconnected․ Verify wiring diagrams match your setup to avoid accidental power activation․ Never bypass safety devices, and ensure all connections are secure․ Use properly rated tools and materials․ Keep the work area clean and well-lit․ If unsure, consult a licensed electrician to prevent risks of electrical shock or fire․ Regularly inspect equipment for damage․ Proper grounding is essential for safe operation․ Adhere to local electrical codes and manufacturer guidelines to maintain safety standards throughout the process․

4․1․ Essential Safety Procedures

When working with transfer switch wiring diagrams, always disconnect power sources before starting․ Use personal protective equipment (PPE), including insulated gloves and safety glasses․ Ensure the circuit is de-energized using a voltage tester․ Follow lockout/tagout procedures to prevent accidental power restoration; Verify the wiring diagram matches your specific transfer switch model․ Avoid shortcuts, as they can lead to dangerous situations․ Use tools with insulated handles to reduce shock risks․ Keep the work area well-ventilated and free from flammable materials․ Never bypass safety features like circuit breakers or fuses․ If uncertain, consult a licensed electrician․ Regularly inspect wires and connections for damage․ Always refer to the manufacturer’s manual for specific safety guidelines tailored to your equipment․

4․2․ Understanding Circuit Protection

Circuit protection is critical in transfer switch wiring diagrams to safeguard electrical systems from overloads, short circuits, and voltage spikes․ Devices like circuit breakers and fuses act as the first line of defense, interrupting power flow when anomalies occur․ Proper sizing and rating of these devices ensure they can handle the maximum current safely․ Transfer switches often include built-in protection or require external circuit protection devices․ Always match the protection devices to the load and power source specifications․ Regular testing and inspection of circuit breakers and fuses are essential to maintain reliability․ Ensure all connections are secure to prevent arcing or excessive heat buildup;

4․3․ Role of Earth Leakage Switches

Earth leakage switches, also known as residual current devices (RCDs), play a vital role in ensuring electrical safety in transfer switch wiring systems․ These devices detect even minor imbalances in current flow between live and neutral wires, indicating a potential ground fault or leakage․ By tripping the circuit, they prevent electrical shocks, fires, or equipment damage․ In transfer switch installations, RCDs are essential for protecting users and equipment from hazardous conditions․ They should be installed in line with the wiring diagram and regularly tested to ensure functionality․ Earth leakage switches are a critical component for compliance with safety standards and reliable operation․

Step-by-Step Installation Guide

A comprehensive guide outlining the sequential process for installing transfer switches, ensuring safety, efficiency, and compliance with electrical standards․ Follow detailed steps for a successful setup․

5․1․ Preparing the Site and Tools

Before starting the installation, ensure the site is clean, dry, and well-ventilated․ Gather all necessary tools, including wire strippers, pliers, screwdrivers, and safety gear like gloves and goggles․ Verify the presence of a transfer switch wiring diagram to guide the process․ Ensure all power sources are disconnected to prevent electrical hazards․ Layout the transfer switch and associated components in an organized manner․ Double-check the compatibility of tools and materials with the system specifications․ Familiarize yourself with local electrical codes and regulations to ensure compliance․ Proper site preparation and tool organization are critical for a safe and efficient installation process․ Always refer to the manual for specific requirements․

5․2․ Connecting Power Sources

When connecting power sources to a transfer switch, ensure both the main power supply and the backup generator are properly identified and configured according to the wiring diagram․ Connect the live wires to the appropriate terminals, ensuring secure connections using suitable connectors․ Always turn off the main power supply before making any connections and verify zero voltage with a multimeter; Follow the transfer switch wiring diagram meticulously to avoid errors․ Label all wires clearly to prevent confusion․ After completing the connections, double-check the setup to ensure compliance with safety standards․ Finally, test the system to confirm smooth operation between power sources․

5․3․ Configuring Load Connections

Configuring load connections involves distributing power from the transfer switch to the desired circuits․ Start by identifying and mapping each load according to the wiring diagram․ Connect the load wires to the appropriate output terminals on the transfer switch, ensuring proper polarity and secure connections․ Use the correct wire gauges to match the load requirements․ Double-check that all connections are tightly fastened to prevent loose contacts․ Proper grounding is essential for safety, so ensure the grounding wire is securely attached․ Test the system by turning on each load individually to verify proper power distribution․ Avoid overloading circuits, as this can lead to system instability or safety hazards․

Troubleshooting Common Wiring Issues

Identify faults by testing connections and verifying power flow․ Address issues like power discrepancies or relay malfunctions by consulting the wiring diagram or resetting systems․

6․1․ Identifying Faults in Transfer Switches

Identifying faults in transfer switches requires a systematic approach․ Start by reviewing the wiring diagram to understand connections․ Check for loose wires, blown fuses, or tripped circuit breakers․ Common issues include misaligned switches, faulty relays, or open circuits․ Use a multimeter to test voltage levels at key points․ Look for signs of overheating, such as discoloration or burning smells․ Verify that the switch is properly calibrated and aligned with the power sources․ Ensure all terminals are securely tightened․ If the switch fails to engage or disengage, inspect the actuator or solenoid for damage․ Always refer to the manual for specific troubleshooting guidelines․ Safety is paramount, so disconnect power before performing detailed inspections․

6․2․ Resolving Relay Malfunctions

Resolving relay malfunctions in transfer switches involves diagnosing the root cause․ Start by checking the control circuit for power issues or short circuits․ Inspect the relay contacts for wear or corrosion, as this can disrupt proper switching․ Use a multimeter to test the coil resistance and ensure it matches the specifications․ Verify that the control signals, such as voltage or current, are within the required range․ If the relay fails to activate, check for blown fuses or tripped breakers in the control circuit․ Clean or replace faulty contacts and ensure proper wiring connections․ If the issue persists, consider resetting or replacing the relay altogether․ Always refer to the wiring diagram for guidance․

6․3․ Diagnosing Power Supply Problems

Diagnosing power supply issues in transfer switches requires a systematic approach․ Begin by verifying the input voltage levels using a multimeter, ensuring they match the specifications in the wiring diagram․ Check for loose or corroded connections, as these can cause voltage drops or interruptions․ Inspect the circuit for any signs of short circuits or open wires․ Test the circuit breakers and fuses to ensure they are functioning properly․ If the transfer switch fails to switch, confirm that the power source (e․g․, generator or utility) is operational․ Finally, verify that the control circuit is receiving the correct signal to activate the transfer process․ Always follow safety protocols when working with live circuits․

Best Practices for Transfer Switch Wiring

Adhere to the wiring diagram, ensure proper load management, and follow safety protocols․ Use correct tools and materials, and conduct regular inspections for optimal functionality and safety․

7․1․ Ensuring Proper Load Management

Proper load management is critical to ensure safe and efficient operation of transfer switches․ Always assess the total load requirements of connected devices to avoid overloading the system․ Prioritize critical circuits and balance the load between primary and secondary power sources․ Use load calculators to determine the appropriate sizing of conductors and components․ Ensure that the transfer switch is rated for the maximum expected load to prevent overheating or failure; Regularly review and update load configurations as electrical demands change․ Refer to the wiring diagram to confirm connections align with load specifications․ Proper load management prevents damage and ensures reliable power distribution․ Consulting a professional for complex systems is recommended․

7․2․ Avoiding Common Installation Mistakes

Avoiding common installation mistakes ensures a reliable and safe transfer switch system․ Begin by carefully following the wiring diagram to prevent incorrect connections․ Double-check the compatibility of components with the power sources and loads․ A frequent error is miswiring the neutral and ground terminals, which can lead to system malfunctions․ Ensure all connections are secure and tighten them properly to avoid loose contacts․ Another mistake is neglecting to test the system after installation․ Always verify the transfer switch’s operation under load conditions․ Improper sizing of conductors or circuit breakers can cause overheating or failure․ Use the correct tools and materials to maintain system integrity․ Regularly inspect connections for signs of wear or damage․

7․3․ Regular Maintenance Tips

Regular maintenance is crucial to ensure the optimal performance and longevity of transfer switch systems․ Start by inspecting all connections and terminals for tightness and corrosion, as loose connections can lead to power failures․ Clean the switch contacts periodically to remove dirt or debris that may interfere with operation․ Lubricate moving parts, such as hinges and levers, to ensure smooth transitions between power sources․ Check for signs of wear or overheating, such as discoloration or unusual odors․ Schedule annual professional inspections to identify and address potential issues early․ Replace worn or damaged components promptly, and keep a record of maintenance activities for future reference․

Understanding the Manual Transfer Switch Wiring Diagram

The manual transfer switch wiring diagram provides a detailed visual guide for connecting power sources, ensuring safe and efficient switching between primary and backup systems․

8․1․ Labeling and Interpretation

Proper labeling is crucial for interpreting a manual transfer switch wiring diagram․ Each component, such as power sources, loads, and control circuits, should be clearly marked․ Color coding and symbols help differentiate between primary and backup power lines, ensuring safe connections․ Understanding the labels allows technicians to identify the purpose of each terminal and wire, preventing installation errors․ Key elements include input/output designations, relay contacts, and grounding points․ Accurate interpretation ensures the switch operates correctly, transferring power seamlessly during outages․ Always refer to the manufacturer’s legend for specific symbols and notations to avoid misconnections and ensure compliance with safety standards․

8․2․ Parameter Settings for Optimal Functionality

Setting the correct parameters is essential for ensuring the manual transfer switch operates efficiently․ Voltage, current, and frequency ratings must match the connected loads and power sources․ Transfer time should be configured to minimize downtime during switching․ Sensitivity adjustments for voltage and frequency monitoring prevent unnecessary transfers․ Delays for reconnection ensure stability before restoring power․ Proper parameter settings prevent overload conditions and ensure smooth transitions between power sources․ Referencing the manufacturer’s guidelines guarantees compatibility and safety․ Regularly reviewing and updating these settings ensures optimal performance and reliability in varying operational conditions․

8․3․ Integrating with Generator Systems

Integrating a manual transfer switch with a generator system ensures a seamless power transition during outages․ Proper wiring connections between the generator, transfer switch, and load center are critical․ The transfer switch must be compatible with the generator’s power ratings and phase configuration․ Installing a dedicated circuit for the generator prevents overloading and ensures safe operation․ Testing the system under load conditions verifies proper functionality․ Regular maintenance, such as checking connections and exercising the generator, ensures reliability․ Following the manufacturer’s guidelines for integration guarantees system performance and safety․ This setup provides a reliable backup power solution for critical loads during utility failures․

Understanding transfer switch wiring diagrams is essential for safe and efficient electrical system management․ This manual provides comprehensive guidance for installation, troubleshooting, and maintenance, ensuring reliability and safety․

9․1․ Summary of Key Points

A transfer switch wiring diagram manual is a crucial guide for ensuring safe and efficient electrical system management․ It covers the purpose and types of transfer switches, such as automatic and manual options, and their differences․ The manual emphasizes the importance of proper wiring diagrams for installation and troubleshooting․ Key components like power sources, relays, and circuit protection devices are highlighted, along with safety precautions and maintenance tips․ By following the manual, users can ensure reliable power transfer and system functionality․ It serves as a comprehensive resource for both beginners and experienced professionals, promoting safety and efficiency in electrical installations and operations․

9․2․ Final Safety Reminders

Always prioritize safety when working with transfer switch wiring diagrams․ Ensure the power supply is turned off before starting any installation or maintenance․ Use insulated tools and wear personal protective equipment (PPE) to prevent electrical shocks․ Follow the manufacturer’s instructions meticulously to avoid system malfunctions․ Never overload the transfer switch, as it can lead to fire hazards․ Regularly inspect the wiring and connections for wear or damage․ Ensure proper grounding to safeguard against earth faults․ Remember, safety is non-negotiable when dealing with electrical systems․ Adhering to these guidelines will help prevent accidents and ensure reliable operation of your transfer switch setup․

9․3․ Resources for Further Learning

For deeper understanding, refer to official transfer switch wiring diagram manuals provided by manufacturers․ Websites like Schneider Electric and Eaton offer detailed guides and tutorials․ Books on electrical wiring and codes, such as the NEC Handbook, are invaluable․ Online platforms like Coursera and Udemy provide courses on electrical systems․ Forums and communities, such as Reddit’s r/electrical, offer practical insights․ YouTube channels specializing in electrical work demonstrate hands-on techniques․ Always consult licensed professionals for complex setups․ These resources ensure you stay updated and proficient in transfer switch wiring, enhancing both safety and efficiency in your projects;